People don't invest in projects; they invest in problems, solutions, and outcomes. This includes your maintenance team and as a team leader, you need to stand out from the crowd and get business leaders to buy into your vision for your maintenance project.

In this post, we’ll explore the six steps for building the perfect pitch for your next maintenance project, along with storytelling tips and advice on what data points to include.

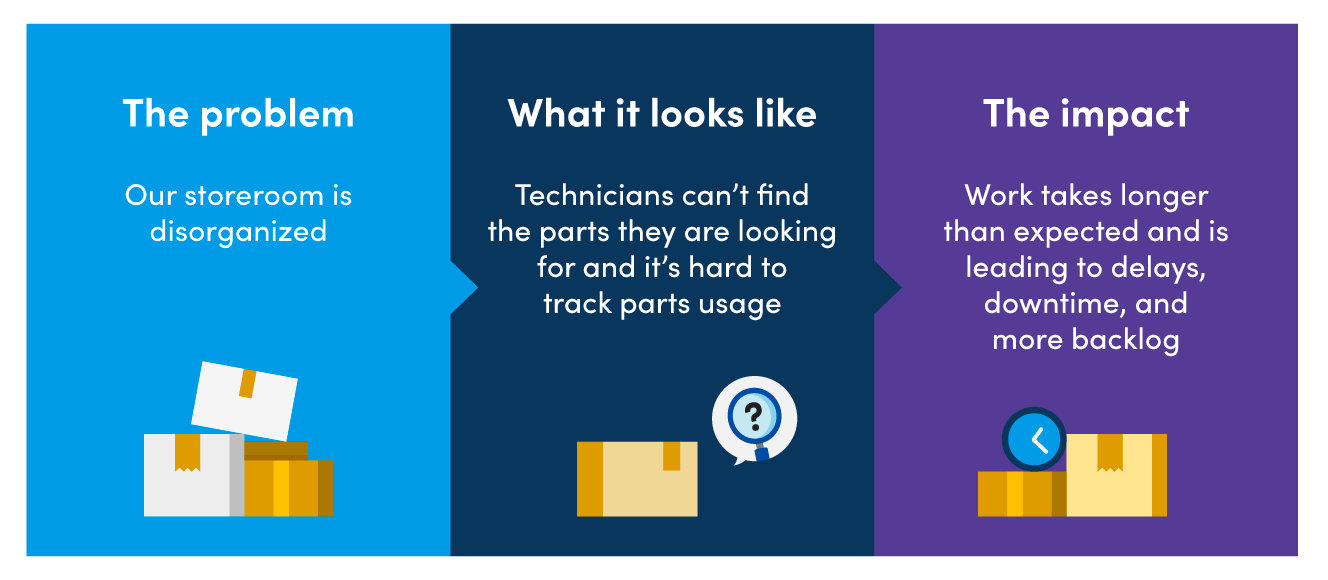

Step #1: Present a problem

Your project is a change, and change is sometimes hard to accept. Find a problem that your project will solve and run with it.

How to tell the story:

- Describe the problem

- Show what the problem looks like

- Explain the impact of the problem

Examples of data to include:

- Cost: How much is the problem costing your team?

- Time: Are you spending more time than you should on a task?

- Health and safety: Are audit compliance tasks not getting done, or are near misses getting higher?

- Employee retention: Is it hard to hang on to good team members?

- Quality: How is a deficiency for your team affecting the end product?

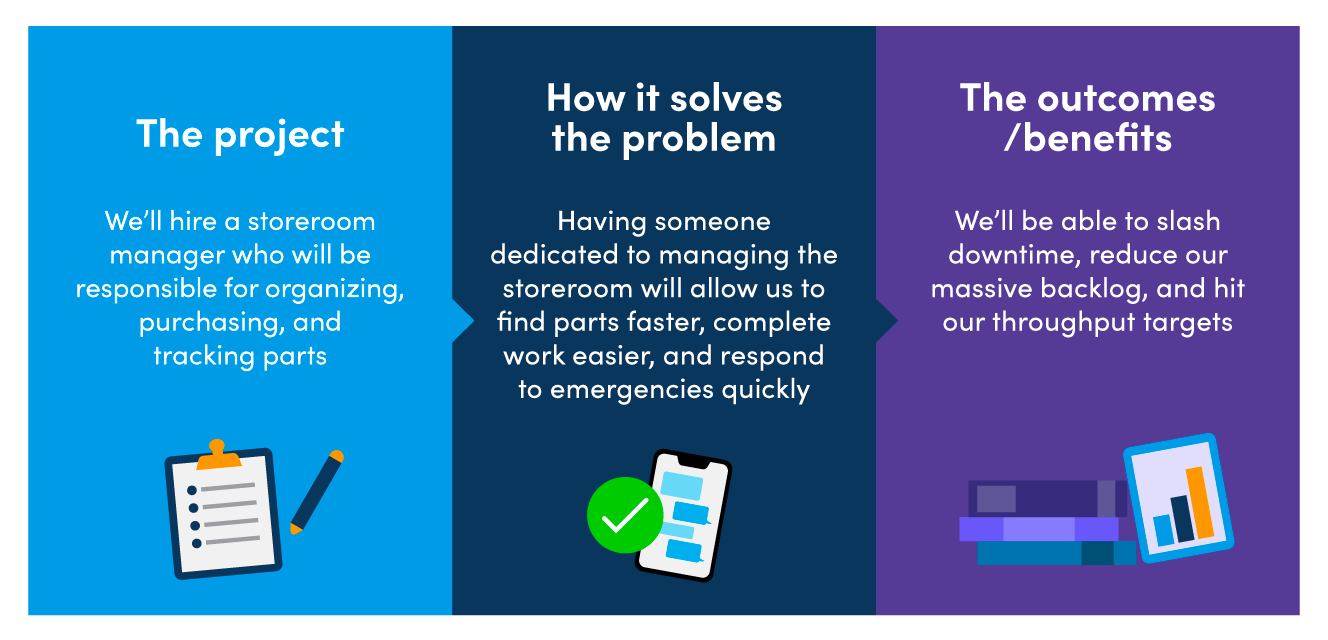

Step #2: Outline a solution

Now that your problem has been identified, it’s time to introduce your project. Remember, people are less likely to poke holes in a project if it answers a problem they worry about.

How to tell the story:

- Describe your solution/project

- Explain how it solves the problem

- Outline the outcome/benefits

Example of data to include:

- Find out how many labor hours you could save if technicians didn’t need to spend their time searching for parts.

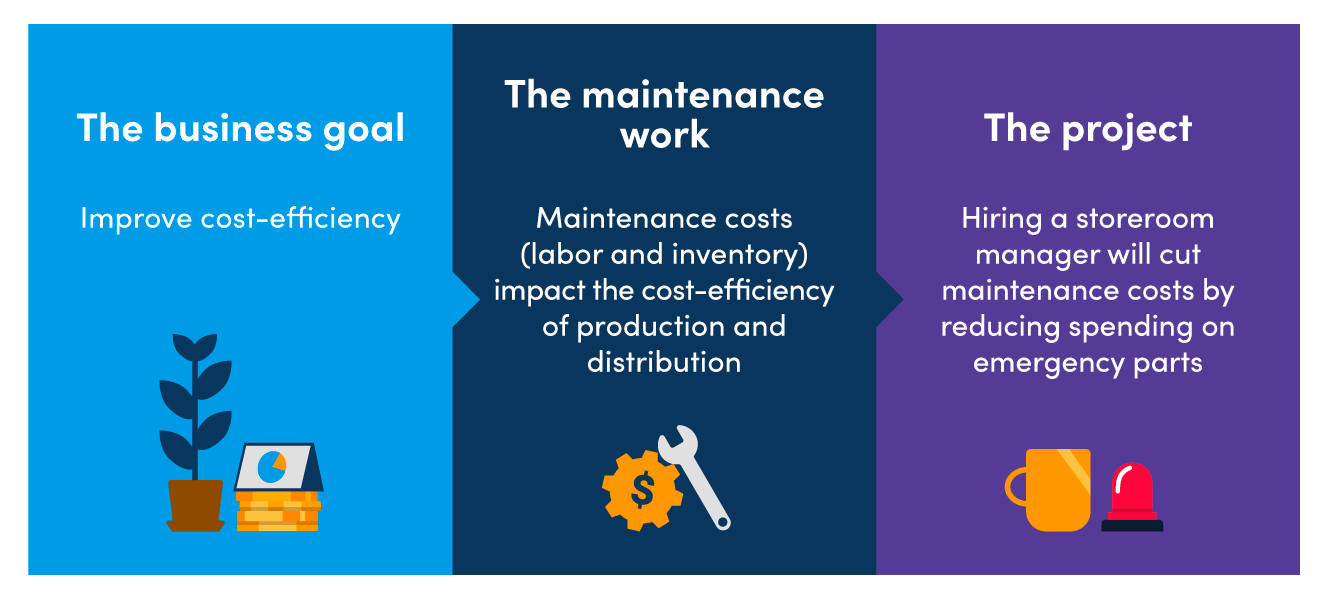

Step #3: Align your solution with business goals

If your project gets people closer to hitting their targets, you’re more likely to get their support. It turns your project from something the maintenance department wants to do to something the business has to do.

How to tell the story:

- Determine the goals of the business

- Connect those goals to maintenance work

- Tie that work to your project

Examples of how to tie data to business goals:

- Cost efficiency: Hiring a specialist will allow us to cut contractor costs by $100,000 a year and increase production time by 8% a year

- Expansion: Buying maintenance software gives us the power to standardize maintenance processes so we can set up new maintenance teams in 30 days instead of 60.

- Risk reduction: A dedicated inventory manager will track and forecast parts usage so we can prepare for supply chain disruptions and cut emergency purchases by 40%.

Step #4: Prove the project will work

There’s been a lot of skepticism around new projects simply because people fear the unknown. Proving your project will work is essential to getting it approved.

How to tell the story:

- Find case studies/examples of other companies that have done the same project with good results (bonus points if it’s a competitor or a well-known company).

- See if another team or site at your company has gone through a similar project and what the positive outcomes were (e.g., how have maintenance teams at other sites approached the problem you’re trying to solve?)

- Conduct a small experiment or pilot of your idea and present the findings.

How to use the data you’re collecting from other sources:

- Take these results and translate them to fit your team and the scale of the project.

- Example: another company may have seen 30% fewer breakdowns after installing sensors on all their machines. But what if it’s only realistic for you to monitor sensor readings on a handful of assets? Will it yield the same results?

Step #5: Identify risks

Every project has its risks, so anticipating these road bumps shows that you’re prepared to navigate around them without spending too much time or money. Pair each identified risk with a plan to conquer it.

How to tell the story (by pairing risks with plans):

- Risk: Technicians won’t use the software we’re introducing

- Plan: Involve them in the selection process so they’re comfortable with the system

- Risk: It will take longer than we think to onboard a new hire

- Plan: Record short tutorials for routine tasks to shorten the learning curve)

- Risk: Our backlog will get bigger while we implement the project

- Plan: Develop a system to prioritize and complete backlogged work to reduce risk

Examples of red flag data to use:

- Costs

- Completion rates for project tasks

- Backlog of project tasks

- Data quality

- Employee satisfaction

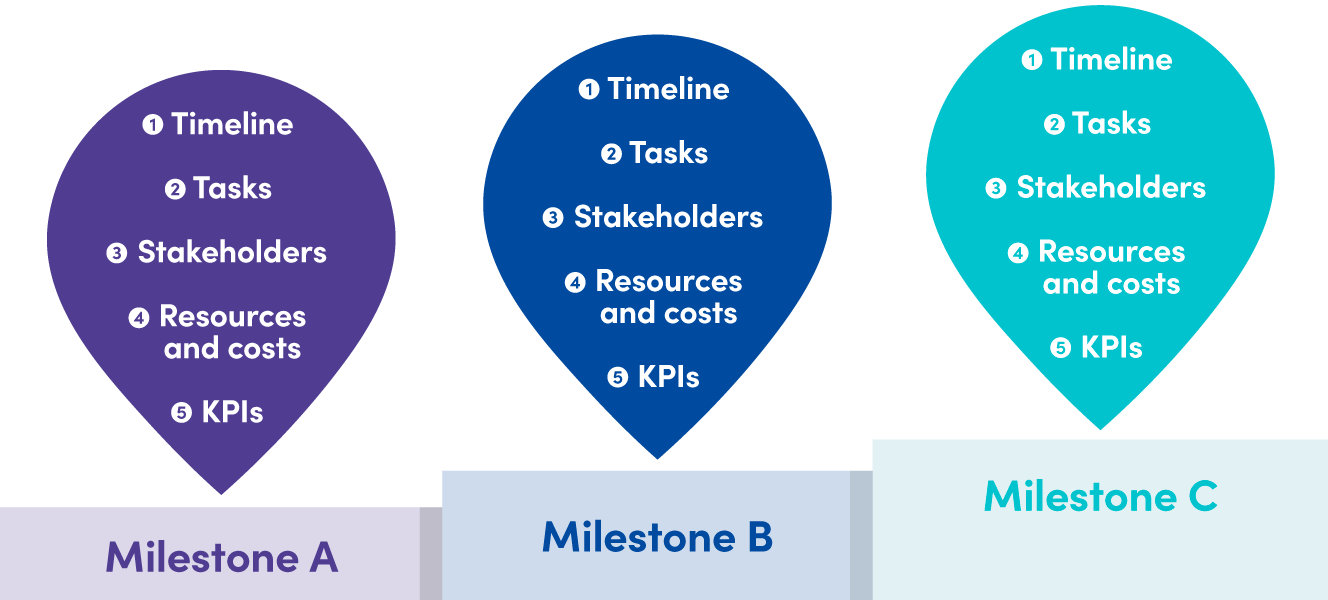

Step #6: Outline your plan and requirements

Finally, fill out the specifics of your plan so everyone understands how it will affect you, your team, and the rest of the company. By doing this, you’re showing how the resources and support you’re asking for will be used efficiently to produce reliable results faster.

How to tell the story:

- Timeline: How long will this step of the project take?

- Tasks: What will you accomplish at this step of the project?

- Stakeholders: Who will be involved at each step, and how involved they should be?

- Resources and costs: What resources will you need to accomplish each task and how much will they cost?

- KPIs: How will you measure success at each stage?

How to set yourself up for success with data:

- Define your success metrics (e.g., Time to retrieve parts)

- Set benchmarks (e.g., It takes ~20 minutes to retrieve parts)

- Track 90-day progress (e.g., The average time to retrieve parts has dropped by 33% over the last 90 days)

So the next time you need to justify your budget, pitch an idea, or just want a vote of confidence for a new process, just remember that storytelling and data are your best friends.

What advice do you have for those looking to get their maintenance project approved?

Share your real-life experiences below👇.