This article was written by Katie Allen, Fiix Alumni.

Katie’s article remains very much relevant today as we celebrate Earth Day, and take action as individuals and organizations to look at our world through an environmentally-conscious lens.

Waste. Garbage. Rubbish. Litter. Trash. Excess. These concepts are relatively new in our modern world. Waste was often synonymous with barren land and had nothing to do with disposal.

Garbage — the act of throwing something away — was introduced in the early 1900s. Now, it’s a regular part of life— we buy, we use, and then we throw away. This is so common that we have entire waste management systems with teams of people and machinery dedicated to our garbage.

This used to be my job. I would advise the public on where to put items when they were ready to throw it out. I would pick through big, black garbage bags on gruelling hot days, dissecting, weighing, and sorting what people threw out. I helped divert hazardous and electronic waste from entering the landfill. I even managed a vermi-composter.

But in all my years doing this work, I never once offered a way for people to fix their stuff so it didn’t need to be tossed out in the first place.

We focused so heavily on reduce, reuse, and recycle that we forgot the most important ‘R’: Repair — the act of looking after your stuff.

We were not the only ones to miss this. It’s not common to receive a maintenance or repair manual when purchasing a product. You often need to search the web to find a community post or a video on how to fix something.

Maintenance and repair is regarded as a mundane practice in our society instead of being recognized as a sustainable approach to product consumption and creation. While we focus on the next, new, shiny thing, we forget the infrastructure, products, and equipment we already have.

The 12th UN Sustainable Development Goal focuses most heavily on addressing this deficit with the circular economy. The goal states that, “Responsible consumption and production” will help us decrease our reliance on natural resources, increase sustainability reporting, reduce waste in all forms, and ultimately encourage lifestyles that are synonymous with nature.

While this is a highly ambitious and admirable goal, they are missing a critical component: Maintenance and repair. Maintenance is the primary method for life cycle management. While it is important to rethink the way we design products (and the machines that make them), as well as how we recycle them, we need to think about the way we actually use the product. This is key to understanding the circular economy and how we can use it to bolster our efforts for sustainability.

What is the circular economy?

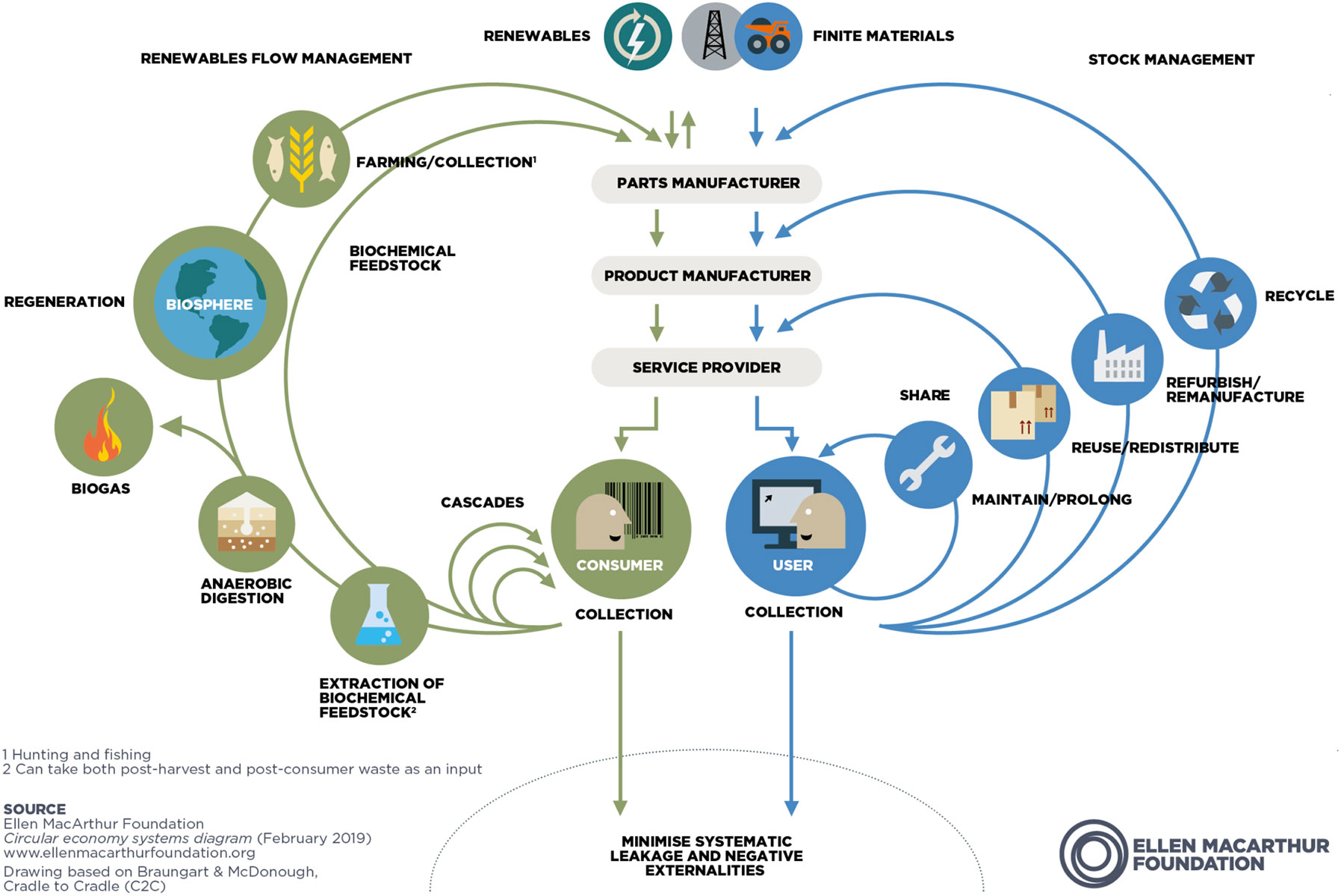

The Ellen Macarthur Foundation is leading research on the circular economy and defines it as a system “based on the principles of designing out waste and pollution, keeping products and materials in use, and regenerating natural systems.”

We currently function in a linear economic system based on a take-make-waste model. Many of the resources we extract are used and eventually wasted.

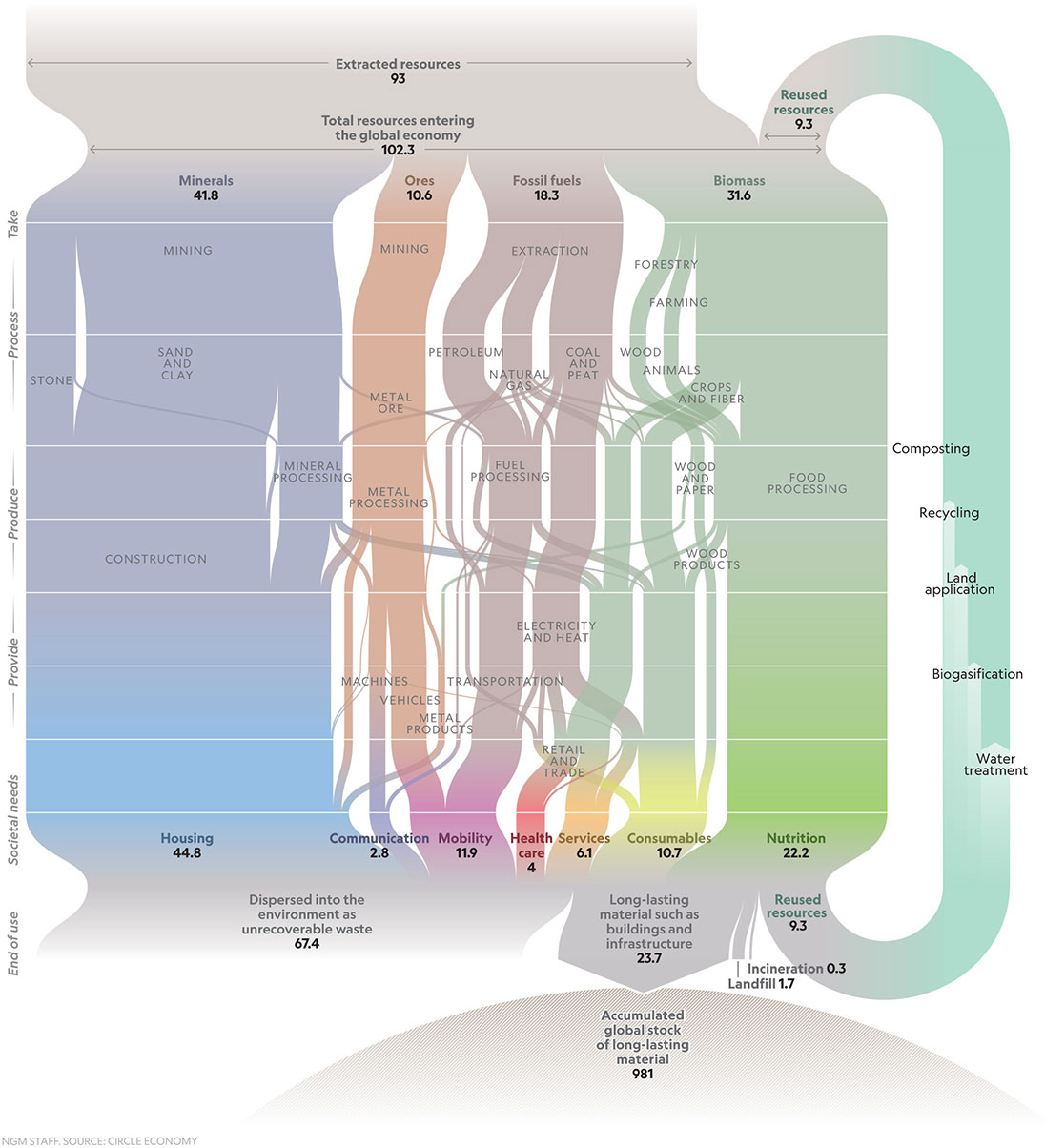

This system is problematic for many reasons. Its inefficiency is wreaking havoc on our natural world with mass amounts of waste and pollution, which also negatively impacts our most vulnerable societies. This system is depicted in the graphic below. It maps all our global resources from extraction to end-of-use. Minerals, ores, fossil fuels, and biomass make up everything from our homes to our food.

As Robert Kunzig points out, “Two-thirds of the material flowing through the economy, 67.4 billion tons in 2015, gets emitted as pollution or otherwise scattered or disposed of as waste.”

While these resources are essential components of our economy, we are witnessing colossal inefficiencies throughout the process resulting in what’s called externalities.

An externality is a cost or benefit of an economic activity experienced by an unrelated third party.

Waste, represented by the grey “end of use” bubbles at the bottom of the graphic, is the most obvious negative externality. Other negative externalities include air pollution, emissions, and the wealth gap.

The circular economy is all about accounting for these externalities. We can phase out waste and pollution from the beginning with responsible design. Through maintenance best practices, we can increase the lifespan of assets, keep material in use, and create greater value socially, environmentally, and economically. And through the regeneration of our natural systems, we can create a thriving, circular economy that works within planetary boundaries.

What is maintenance?

Maintenance is the best way to keep materials in use.

Maintenance is any activity—such as tests, measurements, replacements, adjustments, and repairs—intended to retain or restore a functional unit in or to a specified state in which the unit can perform its required functions.

You can find examples of maintenance in all aspects of your life, from brushing your teeth to changing the oil in your car or washing your dishes. These are all forms of maintenance that keep us and our belongings functioning the way they were intended to.

In industrial settings, maintenance is performed through a variety of strategies that best suit the asset in question. Typically, these strategies are applied to some of the biggest machinery and equipment in the world. Some examples include managing air flow and air quality in electrical and HVAC units, replacing filters, cleaning bearings, pumping tires, and fixing conveyor belts, reactors, and pumps. This takes place in factories, food processing and energy production facilities, data centers, and manufacturing plants.

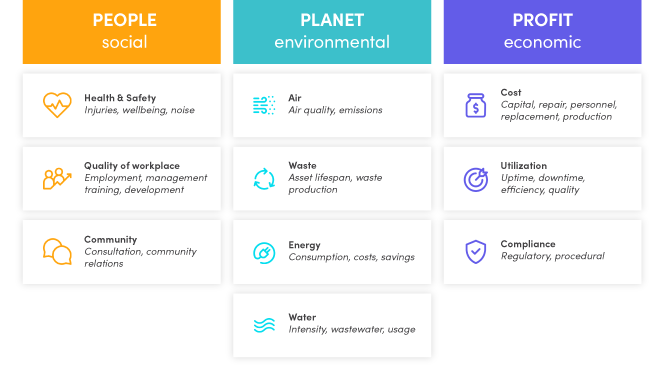

Maintenance and repair strategies keep many of these operations running efficiently, supporting very large, positive outcomes across the triple bottom line of sustainability: People, planet, and profit.

Benefits of maintenance

The Ellen MacArthur Foundation showcases the different elements of the circular economy in the map above, The smaller circles represent the most efficient solutions in terms of cost, materials, and resources.

Here, maintenance makes up the smallest circle, and thus the most efficient and accessible solution. This is because, at its core, maintenance is about keeping the same equipment, materials, and assets in use. With rising costs of raw materials and end-of-life treatment, maintenance becomes a very attractive solution to kick-start the circular economy and build momentum in a more sustainable direction.

In Sobral and Ferreira’s 2018 article, they argue that the fundamental principles of maintenance — continuous improvement, improving performance, and increasing lifespan — are the foundation of Lean Thinking. The main objective of Lean Thinking is to improve society while eliminating waste. Maintenance and efficiency go hand-in-hand, creating positive outcomes beyond just eliminating waste. An effective maintenance strategy can result in improvements across the triple bottom line, as highlighted in the graphic below:

Socially, better maintenance practices can improve health and safety, the quality of workplaces, and the local community. In various studies, it has been reported that better maintenance is associated with lower injury frequency, and when done poorly, maintenance accounts for 10% of workplace incidents.

Environmentally, maintenance can improve air quality, reduce emissions, and reduce waste. It can also prolong asset lifespans, reduce energy consumption, and reduce water consumption. A preventive maintenance program can result in 20% savings in raw material usage. In the residential sector, regular maintenance can save up to 35% of energy costs. In vehicles, researchers found a 30% reduction in emissions following maintenance.

Economically, maintenance reduces costs, improves utilization, and aids with compliance. These are the most common indicators of success. In some instances, predictive maintenance can save up to 12% of costs and decrease downtime by up to 45%.

Measuring all the ways in which maintenance has an impact is critical to the success of any organization. Highlighting these efficiencies and giving maintenance the credit it deserves will help advance the circular economy.

Barriers to success

As it stands today, maintenance isn’t prioritized or recognized. The Maintainers, a think tank based in Washington, D.C., have long sung the praises of maintenance and repair. They examine our obsession with innovation and our disregard for the mundane.

Maintenance and repair, the building of infrastructures, the mundane labour that goes into sustaining functioning and efficient infrastructures, simply has more impact on people’s daily lives than the vast majority of technological innovations.

We are so focused on new things, whether physical or conceptual, that we fail to recognize the critical, overlooked, and underpaid role that maintenance plays in our society. Failing to meet our maintenance needs can have catastrophic consequences. The ongoing cost of maintenance and repair is often undervalued when building infrastructure. That’s when things break, crack, and deteriorate.

In 2019, America’s infrastructure was given a report with a final grade of D+. A team of 28 civil engineers from across the country analyzed everything from energy infrastructure to railways and schools. They found that nearly everything was deteriorating to a point of concern, with most infrastructure approaching the end of its service life.

The impact of this is frightening, costing the US millions of jobs and trillions of dollars in GDP, while externalities are going unmeasured, costing us in pollution and health and safety.

COVID-19 showed us that it’s up to us to keep the world running, and when we stop, we notice. Technical maintenance is often seen as a cost centre rather than an opportunity to save money, time, energy, and waste. The current narrative surrounding maintenance is not exciting, nor is it measured properly, so we don’t understand its full value and potential.

Maintenance and repair needs a rebrand and a re-education campaign. It must be considered as a key source of efficiency in the circular economy and we should be placing resources in these areas to understand how to improve practices.

Technology is helping with this rebrand. Tools, like CMMS software, help organizations track, schedule, and organize maintenance activities. Tracking data is critical. Analyzing that data using artificial intelligence can enable companies to find trends and areas for improvement. Utilizing technology can help bring light into what was once a black hole of information.

Driving the circular economy forward with better maintenance

There are three factors at play that will help us advance the circular economy through better maintenance.

First, the maintenance, reliability, and asset management space needs to recognize and prioritize the best sustainability practices from this line of work and measure it. Technology will be critical in capturing this information.

Second, circular economy research and advocacy must incorporate maintenance and repair as critical steps in advancing sustainability.

Lastly, organizations must adopt technology that enables these best practices. Without adequate data collection, measurement, or management, many of these benefits are lost and aren’t accounted for.

We don’t have to reinvent the wheel as we reach for sustainability. We just need to look after what we already have.

Maintenance and repair are the primary method for life cycle management and essential to understanding the circular economy. How do you and your team practice sustainability in maintenance and increase the lifespan of assets? Share your tips and best practices in the comments section below, we’d love to hear from you! 👇