If you look at the top businesses in almost any industry they all have one thing in common: data is a key part of what fuels their greatness. It makes good teams great and great teams the best. One of the best examples of this is in sports

The conversation around data in sports was almost non-existent 20 years ago, as illustrated in these examples:but we can look at a few key examples to see how this has evolved over time:

-

The MLB’s Oakland Athletics used data to pinpoint the right metric to maximize their offensive outputs (and win more games)

-

F1 teams used data to run over 2 billion simulations of every race to figure out everything from the best tires to use to when to pit stop

-

College football teams like the University of Virginia used data to recruit players they think are most likely to make it to the NFL

So how does this apply to the maintenance world? In this article we’ll explore the three ways data fuels greatness and how you can apply these learnings to your maintenance strategy.

Data helps overcome common roadblocks

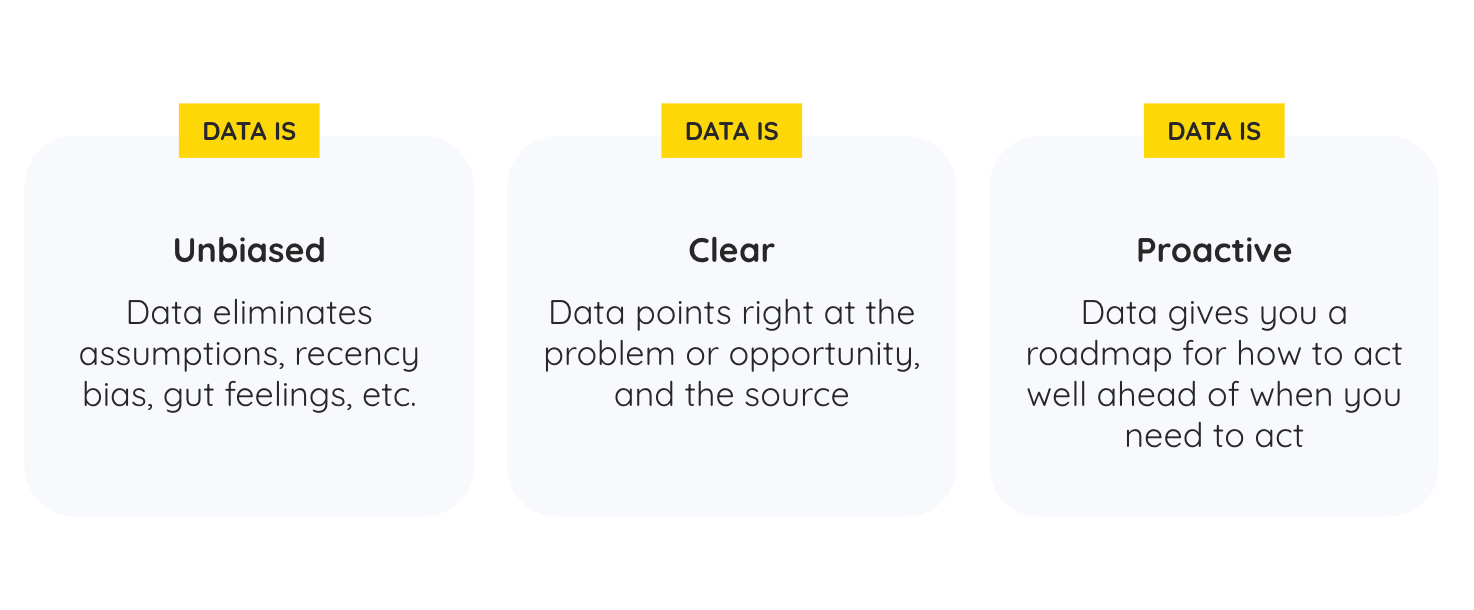

Great organizations understand that part of what makes data powerful is that it reduces or eliminates a lot of the roadblocks to greatness, like:

-

Bias: Data eliminates assumptions, recency bias, and gut feelings. There’s no room for the “that’s how we’ve always done it” attitude.

-

Guesswork: Data points directly at the problem or opportunity and the source so you can come up with a solution and resources to tackle it.

-

Reactive: Data gives you a roadmap for how to act well ahead of when you need to act.

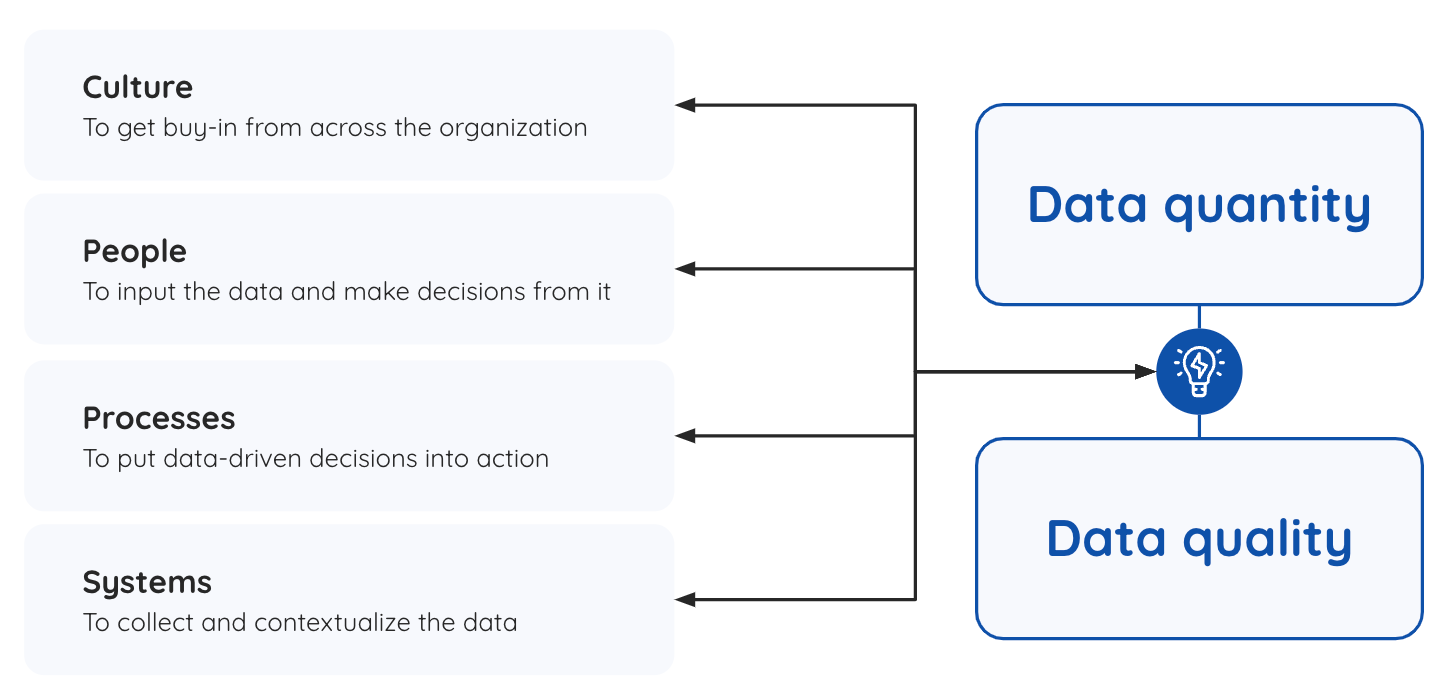

Data needs structure to be actionable

Most companies and teams just start and end with data collection, but great teams have a different way of thinking. They start with a strong structure, the right inputs, and a clear goal in mind, which lets them create a lot of really good data, which they can use to make decisions that get them closer to this goal.

To this, you need these critical elements:

-

Culture to get buy-in from across the organization

-

People to input the data and make decisions from it

-

Processes to put data-driven decisions into action

-

Systems to collect and contextualize the data

Focus on the power of marginal gains

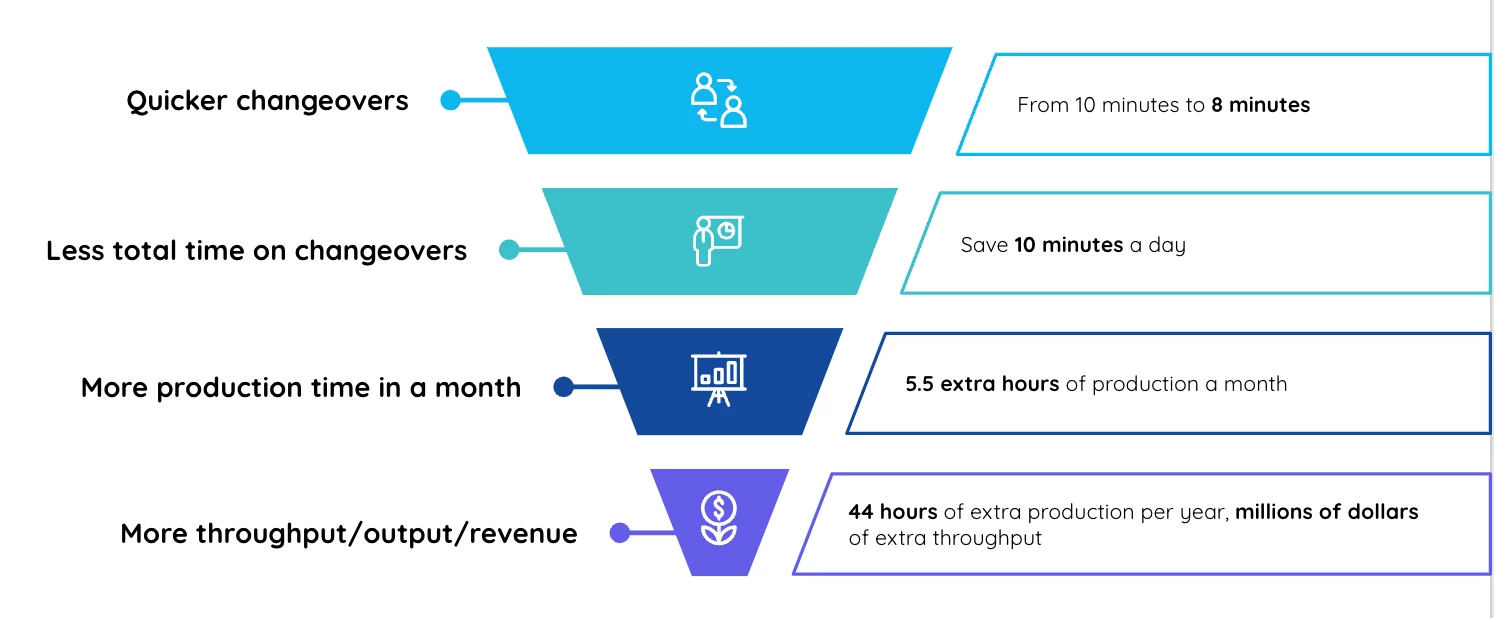

Elite teams understand that the distance between good and great is significantly shorter than the distance between great and the best, and that data can help accelerate that journey.

When you start out trying to find ways to get better, there are often a lot of really obvious and big things you can do. But as you excel at making things better, it becomes much harder to identify areas for improvements.

Marginal gains is all about finding ways to get 1% better in 50 areas rather than getting 50% better in one area. For example, if a cyclist in the Tour de France can reduce air resistance by 1%, it could mean being 15 minutes faster through the entire race, which is often the difference between the middle of the pack and the top competitors. Data allows those teams to find, implement, and track that 1% in those 50 areas.

Let’s look at a more maintenance-focused example. Imagine your team is able to be just two minutes quicker at shift changeovers (going from 10 to 8 minutes). On a daily basis it might not make much of a difference, but over a month or a year, it could mean the difference between failing behind or completing a big order that will put more revenue in your company’s pockets (and more money into your budget for next year).

Good news: you’re already well on your way to fuelling greatness

Just by logging the day-to-day tasks you’re doing anyway, you’ve already accumulated a ton of valuable data. Each and every work order you log in the system has so much information, from the parts you used, to the time it took, to the cost of labor. The data is all there for you; it just needs to be unlocked and unleashed to become actionable insights.

How are you using maintenance data today to fuel your team for tomorrow? Share in the comments below.