This article outlines everything you need to know about planned maintenance percentage (PMP), including what it is, how to calculate it, and how to use PMP to improve your maintenance planning.

What is PMP?

It’s never a good idea to walk into a supermarket without a grocery list and twice as dangerous if you’re hungry. Without a plan, it’s easy to get overwhelmed, forget items, and spend too much on unnecessary ingredients.

PMP calculates the amount of planned vs. unplanned maintenance at your facility. In other words, it tells you if you’re controlling maintenance or if maintenance is controlling you.

– Tanya Goncalves

All these problems are magnified when it comes to maintenance. Unplanned maintenance wastes a lot of time and money while setting production back several steps. That’s why planned maintenance percentage is a crucial maintenance metric. PMP calculates the amount of planned vs. unplanned maintenance at your facility. In other words, it tells you if you’re controlling maintenance or if maintenance is controlling you. Tracking, analyzing, and improving PMP leads to improved processes, less downtime, better schedules, and optimized resources.

PMP formula

Before you calculate PMP, it’s important to understand the difference between planned and unplanned maintenance.

Planned maintenance anticipates work and creates a process for completing it, from start to finish. Preventive, condition-based, predictive, and run to failure maintenance are all types of planned maintenance. Planned maintenance cannot be reactive.

Unplanned maintenance is any maintenance that is not anticipated beforehand. It is unexpected and not part of the normal flow of maintenance activities. Unplanned maintenance and reactive maintenance are often used interchangeably. However, all types of maintenance can be unplanned. For example, a technician might repair one part of an asset and notice that another part is deteriorating. The technician replaces that part before it causes failure. This is unplanned preventive maintenance.

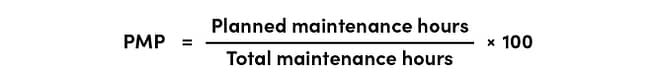

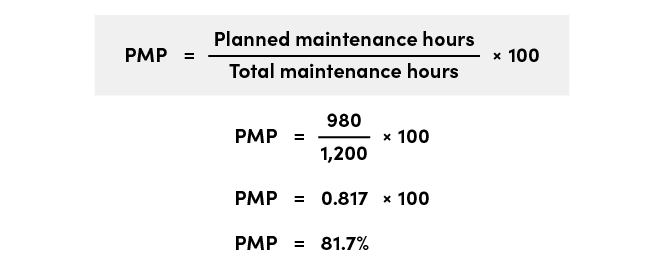

To calculate planned maintenance percentage, start by dividing the number of planned maintenance hours by the number of total maintenance hours in the same period. Multiply this number by 100 to find the final percentage.

For example, let’s say every maintenance task over the last month added up to 1,200 hours. Of all those hours, 980 of them were spent on planned tasks. That would mean that your PMP would be 81.7%

Receive a crash course in maintenance metrics ➡ Get the guide

Benchmarking PMP

World-class PMP is considered to be 85% or higher. However, it’s not enough to hit this number, pat yourself on the back, and call it a day. To truly understand if your organization is achieving best-in-class results, you must look at PMP alongside preventive maintenance compliance.

On average, about 50% to 80% of planned maintenance is preventive. However, planning is just the first step. For preventive maintenance to be effective, it must be done consistently and on time. PM compliance is a maintenance metric that allows you to measure these two factors. When PM compliance is low, the work planned isn’t getting done. Your efforts to boost PMP won’t lead to tangible benefits, like less downtime or reduced costs.

World-class PM compliance is 90%. If your facility isn’t hitting anything close to this target, there are some strategies for improving PM compliance, such as auditing for unnecessary PMs and using mobile maintenance to make PMs easier to complete.

How to improve PMP

Improving PMP is a key part of taking your maintenance planning to the next level. It allows you to better understand how labor, parts, and money are being used. With this information at your fingertips, it’s easier to catch inefficiencies, control costs, and make decisions that prevent failure. Improving PMP involves taking a close look at maintenance processes and using data to optimize those processes.

Make a plan for each asset

Before you can plan maintenance on an asset, you must know which kind of maintenance it requires. There are four main planned maintenance strategies: Preventive, run to failure, condition-based, and predictive maintenance. Choosing the right strategy and the frequency of maintenance involves understanding how assets operate and how they impact your facility.

There are many ways you can arrive at this understanding, including conducting a criticality analysis, determining failure modes, and using metrics, like MTBF. It’s easier to plan maintenance for every asset at your facility after getting to know your equipment a little better, whether that’s daily inspections of a production-critical machine or replacing a light bulb when it burns out.

Improve your response to emergencies

Emergencies happen, no matter how good you are at maintenance planning. However, time spent on unplanned maintenance cuts into time spent on planned maintenance. Giving your technicians easy access to high-quality repair resources helps them solve breakdowns faster so they can get back to planned tasks.

One way to improve your response to emergencies is to build a digital knowledge hub. This is a collection of essential and helpful information accessible in one place and in a digital format. For example, a technician responding to a breakdown could log into a mobile CMMS app and see the history of the asset, repair checklists, diagrams, the location of spare parts, and more. This allows technicians to act fast and get the job done without wasting any time.

Improving PMP…allows you to better understand how labor, parts, and money are being used. With this information at your fingertips, it’s easier to catch inefficiencies, control costs, and make decisions that prevent failure.

– Tanya Goncalves

Establish and improve total productive maintenance

Total productive maintenance (TPM) puts processes and training in place so everyone in a facility—from operations to engineering—is contributing to maintenance. TPM empowers everyone to spot issues and ensure they get addressed before they cause failure. This makes TPM critically important to increasing reliability at any facility.

A great TPM program not only ensures the maintenance team can be notified of issues faster and plan for them, but it also lets those outside of maintenance chip in by completing small tasks. These spreads planned maintenance among more people so more of it can be scheduled. It also frees up the maintenance team to handle emergencies quicker and focus on larger and more skilled planned tasks.

The ultimate benefit of better maintenance planning

Better maintenance planning is the first step in maximizing production at any facility. Planned maintenance leads to more uptime and eliminates the issues that cause delays and waste. Tracking and improving planned maintenance percentage is one way to ensure your maintenance team is doing everything it can to reduce instances of unplanned maintenance and contribute to a successful facility. Taking steps to increase PMP lays bare the inefficiencies in your maintenance planning process so they can be removed, and your team can run like a well-oiled machine.

Do you incorporate maintenance metrics into your planning strategy within your facility? Share with your peers in the comments section below! 💬