In recent years, sustainability and ESG practices have come into the spotlight, pushing the manufacturing sector to adapt to regulatory pressures and shifting consumer expectations. Rockwell Automation's State of Smart Manufacturing Report reveals that a staggering 95% of companies have taken steps to address these concerns.

Maintenance for manufacturing efficiency

Conversations about sustainability and ESG always highlight the importance of maintaining product quality and safety. But following closely is the push to minimize manufacturing waste and promote recycling, signaling a remarkable shift toward embracing the principles of circular economy. The goal? To boost efficiency, make products last longer through repair and reuse, and cut down waste and pollution. Maintenance has a role to play in all of this, using data and analytics to pinpoint manufacturing issues, and maximize the use of existing equipment, materials, and assets, all while minimizing scrap and waste generation. Well-maintained equipment not only decreases waste but also enhances production efficiency, resulting in lower energy consumption.

Maintenance for safer communities

Better maintenance practices also improve workplace quality and benefit local communities. Studies show that improved maintenance correlates with a decrease in injury frequency, with poor maintenance practices contributing to 10% of workplace incidents.

Maintenance for the environment

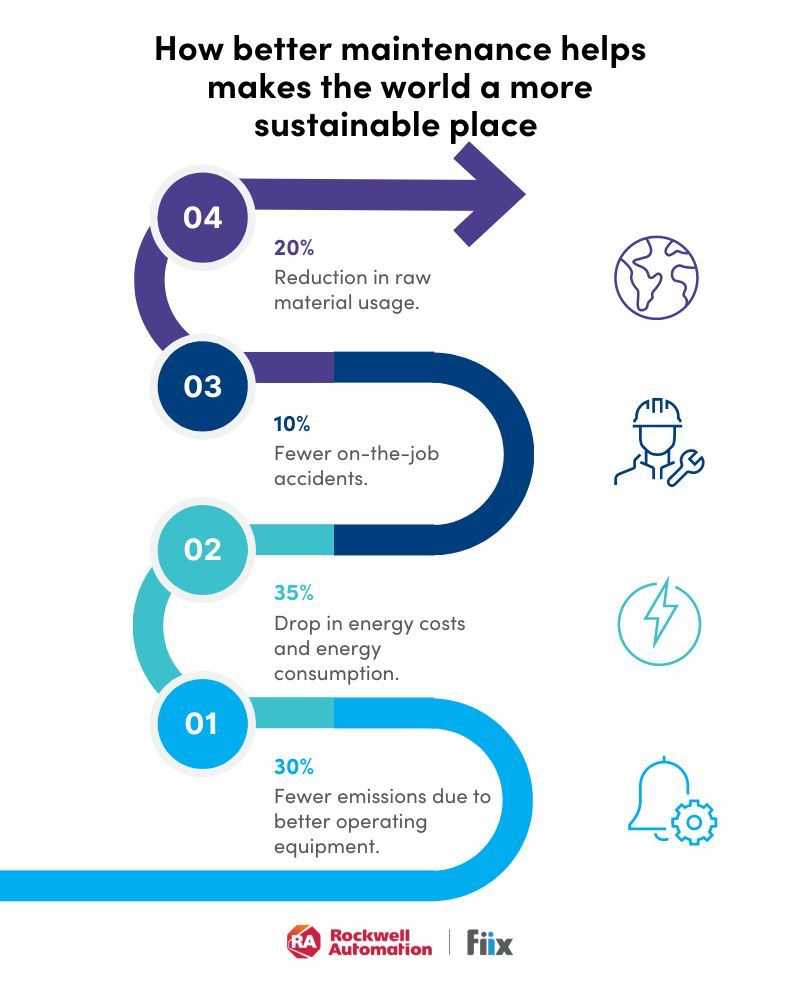

On the environmental side, regular maintenance isn't just good for machines—it's good for the air we breathe and helps cut down on waste and energy use. Preventive maintenance alone can trim raw material use by 20%, slash energy costs by 35% in the residential sector, and a 30% reduction in vehicle emissions. Plus, maintenance can also dial down noise pollution by 40%.

Testimonials from Fiix customers drives home the message of how maintenance efforts can bring about big changes. Voltalia's maintenance crew cut down on over 2,000 hours of travel time, reducing associated emissions. One manufacturing maintenance manager even noticed a 30% boost in energy efficiency thanks to Fiix. This allowed for actions like fewer oil changes and trimming down water and waste, all adding up to their sustainability efforts.

Every day, millions of maintenance professionals work hard to make the world greener and Fiix is here to support them on this mission. Research shows that maintenance programs and check-ups can cut CO2 emissions by 5.6%, scheduled maintenance can improve equipment reliability by 12%, and regular facility upkeep can save up to 35% on energy. These numbers highlight how crucial maintenance is for reaching sustainability goals and creating a greener future for generations to come.

In short, taking care of things isn't just good for business—it's good for the planet too.